Any Printer Can Be Used For Sublimation?

A typical query for newcomers to this procedure is whether they may use an ordinary inkjet printer for sublimation or if they must purchase a professional dye sublimation printer right immediately. In this article we will guide you to know can you use a regular printer for sublimation or not. Read the full article for an in-depth understanding.

The answer is not as simple as it appears. Yes, with careful preparation and expectation setting, existing home printers can be converted to perform basic hobby-level sublimation operations in some circumstances.

However, for the greatest results when producing high-quality sublimated items on a large scale, investing in machines designed expressly for dye sublimation is highly recommended.

This complete guide delves into the use of conventional printers for sublimation in areas such as required inkjet modifications, printable material performance, image quality comparisons, and options for people who are unable to acquire real sublimation hardware upfront.

Read on to see if temporarily attempting sublimation with a conventional printer looks doable or if going directly to dedicated equipment makes more sense in the long run, depending on the circumstances.

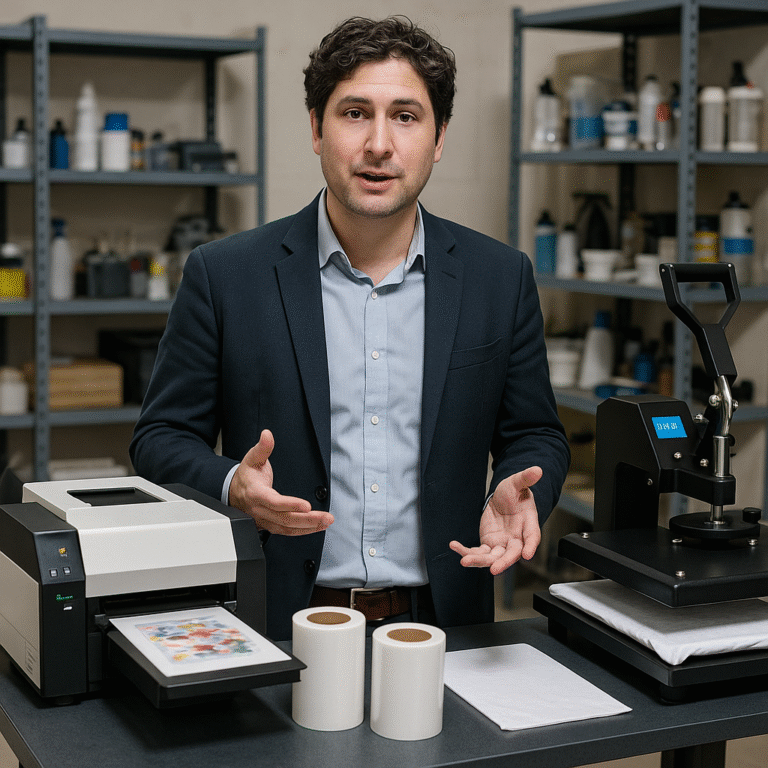

What Is the Difference Between Sublimation Printers and Standard Inkjet Printers?

Before evaluating a standard printer’s sublimation capabilities, it’s important to understand why specialized dye sublimation machines exist in the first place. These process-specific printers have specialized components that are tuned for heat transferring dyes rather than traditional ink adhesion.

Inks for Sublimation

Sublimation uses special ‘dye-based inks’ developed with polymers that evaporate and infuse at temperatures above 400° F, rather than typical ink pigments lying atop print surfaces. This enables dyes to permeate polyester coatings and polymers on blanks such as cups.

Print Quality

Most consumer ‘inkjet printers’ have a maximum resolution of 4800 x 1200 DPI and lack the high dots-per-inch capabilities required for photorealistic sublimation impressions.

Printing Heads

Thicker sublimation inks that are not intended for the heads clog inkjet nozzles. Specialized sublimation printers, on the other hand, have long-lasting self-cleaning print heads developed for gel-based dye inks.

Intensity of Color

Standard printers limit total ink volume per print, whereas sublimation printers use high capacity ink carts with intense color saturation, which is crucial for color accuracy when infusing blanks.

Post-Print Security

Industrial sublimation printers include integrated heat drying units to instantly stabilize prints and prevent smudging during the finishing steps. Tabletop inkjets lack curing capability.

Screen Printing Vs Sublimation

Sublimation Printer Inkjet Printer Modifications

Given the aforementioned intrinsic hardware limitations, the only method to potentially use common document inkjet printers for sublimation is to replace normal ink cartridges with compatible third-party dye-sublimation ink formulations and print profiles.

Several suppliers sell sublimation ink conversion kits for popular Canon, Epson, and HP machines, allowing dye sublimation jobs to be performed. Expect certain trade-offs with this workaround solution path.

Here’s a basic rundown of the process and requirements:

- Reset the ink cart chip591

- Set up sublimation ink reservoirs

- Create supporting color profiles

- Clean print heads on a regular basis

- Reset color mapping values

- Print heads will have a reduced lifespan

- Handle any warranty issues that may arise

While it is becoming possible with meticulous prep procedures, using regular inkjets for sublimation still has significant limitations.

Using Standard Printers with Regular Sublimation Inks

If you’re willing to undergo fiddly setup procedures and parameters for desktop sublimation ink printing, look into suitable dye-ink solutions designed expressly for temporarily converting standard document printers.

Sawgrass controls the global sublimation ink market with its prominent Virtuoso and Xit dye ink lines, which are known for their brilliant and accurate color performance. But it won’t support inkjet printers for sublimation.

So, I have tested a few other sublimation inks on my Epson inkjet printer and would suggest these top 3:

1) Hipoo Sublimation Ink

2) Xcinkjet Sublimation Ink

3) Printers Jack Sublimation Ink

The main benefit of using these sublimation inks is that they are very cheap.

Due to the intricacy of production, expect to pay a premium for these unique third-party sublimation inks.

To avoid nozzle clogging difficulties in the future, ink formulation must be extraordinarily pure throughout manufacture. Sublimation ink bottles are also smaller in fluid ounce capacity than typical printer cartridges, which adds to the cost. How much sublimation printer costs?

Pricing Comparisons:

– 9ml standard ink cartridge = $20

– Sublimation cartridge for 2-3ml = $60

While successfully converting standard document inkjets to work with sublimation dyes is possible with cartridge refills, expect sticker shock when it comes to specialty ink costs.

Sublimation Ink Modded Desktop Printers For Printable Materials

Assuming the desktop inkjet printers are successfully converted with appropriate third-party sublimation inks, the focus will shift to viable substrate blank options playable with these non-industrial rigs.

Premium results are achieved by using commercial sublimation presses and printers designed for high heat and pressure. However, presume that you are establishing expectations appropriately, accepting quality sacrifices, and looking for shortcuts around initial equipment investments.

Having said that, here are the material options that shops can still experiment with when printing with customized sublimation desktops:

Polyester Fabrics

Light 100% polyester textiles, with proper wash and press preparation, continue to offer excellent practice canvases for modified printers. However, when compared to commercial rivals, expect a loss of brightness and precision.

Suggested: HTVRONT Fabrics For Light/Dark Fabrics

Substrates of Hardness

Ceramic mugs, chins plates, aluminum prints, acrylics, and wood still work well in heat presses, but with lower desktop print resolutions and ink limits, they may have slight ghosting or bleeding.

Magnets with Polymer Coatings

Flexible magnetic sheets allow for smaller customized printer widths and fun novelty fridge things to test with partial sublimation process constraints that are well explained upfront about end product performance.

Suggested Product: 30 PCs Sublimation Magnet Blanks 4*6 Size

For More Product Variations: Amazon Page

Leathers made of synthetic materials

The increasing class of synthetic leathers and polymeric vinyls best display outstanding results from desktop dye sublimation machines, which are ideal for designers creating custom wallets, bags, cases, or analytic items who seek economical short-run choices.

Suggested PU Leather Sheets From: Amazon

When heat pressed properly, these materials become forgiving to work with from home desktops.

So, even if you’re limited to regular inkjet printers hacked for sublimation, you can still have fun personalizing tons of bespoke products – just be clear about your expectations and capabilities.

Desktop Sublimation Print Quality Compromises

With appropriate desktop printer modification specifics addressed and compatible substrate materials outlined, shed light on a few of the practically unavoidable print quality sacrifices when attempting dye sublimation with ill-suited everyday document inkjets as temporary alternatives.

While astonishing outcomes are still possible on occasion, expect degrees of the following anomalies when pushing desktop printer transfers in the hopes of consistency:

Ink Bleeding: Standard inkjets lay more ink than sublimation printers, resulting in bleeding around graphic edges and gradations.

Muted Colors: Many simple desktop printers do not achieve the saturation levels of 300%+ required for brilliant poppy images after diffusion, particularly deeper tones.

Inconsistent Transfers: Basic printing components have difficulty distributing the precise ink densities needed print-to-print for polished sublimation work.

Short Print Head Lifespans: Frequent cleaning and clogging cut months off print head expectations for those who aren’t used to dealing with thick saturated sublimation inks on a daily basis.

Inability to Scale: Entry inkjet tray systems can only handle big production runs, which is crucial for growing merch firms that require consistent output.

In conclusion, while converting simple document inkjet desktop printers offers limited dye sublimation capability as an exploratory starting point, it is far from perfect when compared to appropriately scaled commercial gear and risks developing customer satisfaction concerns in the long term.

Sublimation Printing Tutorials

Practical Home Sublimation Alternatives for Converting Common Printers:

Recognizing that desktop sublimation printer mods entail some quality consistency risks and greater running costs as stopgap measures, what other options available for home hobbyists interested in trying bespoke dye sublimation on a budget at first?

Get Desktop Sublimation Printer Kits

Affordable all-in-one desktop sublimation printer kit bundles, such as the ever popular Sawgrass Virtuoso, offer optimized dye sub components designed specifically for home use for under $500.

These simplify setup by eliminating the need for sophisticated inkjet conversions.

Suggested Desktop Sublimation Printer Kits: Amazon Page

Look into Sublimation Printing Services

Third-party sublimation printing firms conduct production work while possessing appropriate commercial equipment.

Users just submit ideas online for low-cost per-piece printing, removing the need for printers to get started.

Examine All-In-One Sublimation Machines

Compact printer+heat press equipment, such as the Epson ET-15000, simplify complete sublimation by requiring only basic image designs and blank goods.

While limited in comparison to professional equipment, these consolidate functionality to a minimum.

Do you mirror sublimation prints?

Hold Off Until Business Volume Is Proven

Rather of overinvesting in the beginning, stay lean by first confirming client need direct-to-consumer before investing in Optimized sublimation equipment. Prioritize product-market fit over production procedures at first.

To summarize, there are several ways to get started with bespoke dye sublimation without requiring sophisticated inkjet printer modifications right now.

Find the path that is most supportive of present business volumes, technical skills, and growth trajectories.

How to upload artwork files to sublimation printer?

Key Takeaways – Sublimation with Regular Printers

While it is possible to try basic dye sublimation printing using normal inkjet desktop printers with careful ink substitutions and profile modifications, keep in mind that optimized results occur when using equipment made specifically for the heat transfer sublimation process.

Expect color inconsistencies, bleeding risks, and high consumable costs when attempting to convert ill-equipped consumer document devices best suited for infrequent text printing.

Consider more beginner-friendly sublimation hardware choices before committing to the customisation art full-time.

Still, experimenting with appropriate desktop printer mods provides a low-cost starting point for evaluating early demand before investing in commercial equipment.

Consider special inks and inkjets as a testing ground for product demand rather than a long-term option for polished dye sublimated production. Please feel free to return if you have any other queries about converting conventional printers. Have fun sublimating!

FAQ’s:

Yes, you can print sublimation paper on a conventional inkjet printer, but it will not provide the same colorful, long-lasting results as a true dye-sublimation printer. Here are the main reasons and constraints to consider:

1) Conventional printers use regular ink rather than sublimation dye inks. This means that instead of effectively bonding during heat transfer, the images will sit on top of the sublimation paper.

2) Without sublimation-specific inks, print quality and color accuracy on high release paper will be worse. Colors will most likely be faded, muted, or incorrect.

3) Because consumer printers lack the required dithering for sublimation transfer profile output, any pictures or gradients will print with banding.

4) Standard printers have lower maximum print resolutions, such as 4800×1200 DPI, whereas excellent sublimation printers have up to 1200×2400 DPI for sharp detail.

5) Print durability will be poor because ordinary ink lies on top of the sublimation transfer sheet rather than being bonded, so even minor friction during pressing could smear or remove inks.

While conventional printers can potentially output some basic designs onto sublimation paper, the results will be dull colors, imprecise hues, banding defects, and fragile print surface integrity when compared to proper dye-sublimation printing. If you’re on a tight budget, invest in a dedicated sublimation printer or employ a third-party sublimation printing service. Please let me know if you have any more inquiries!

Yes, many consumer inkjet printers can be converted into makeshift sublimation printers by employing specific third-party sublimation inks and modified printer profiles. However, there are several constraints to be mindful of.

Here’s a quick rundown of the conversion procedure and tradeoffs:

Converting an Inkjet Printer:

→ Reset the ink cart chip so that third-party ink can be used.

→ Completely flush out the original inks.

→ Set up the sublimation ink reservoir kit.

→ Create ICC color profiles that are compatible.

→ Clean printheads on a regular basis to avoid obstructions.

Limitations Following Conversion:

→ The possibility of losing the printer’s warranty

→ Reduced printhead lifespan due to frequent cleanings

→ Maximum print resolution is limited.

→ Lower peak color saturation as compared to native sublimation printers

→ There is no post-print drying and hardening included.

→ A smaller cartridge size results in a greater ink cost per ml.

While converting document inkjets allows for basic sublimation, expect to pay higher consumable costs over time, struggle with noisy color reproduction, and make lifespan sacrifices owing to inherently compromised desktop printer mechanics that are unsuitable for thick saturated sublimation inks in the long term.

To achieve the greatest results, it is still strongly advised to purchase a specialist dye-sublimation printer designed entirely around high heat transfer quality and capacity rather than simply jury-rigging conversion solutions. However, in a pinch, temporarily tweaking an extra existing inkjet can work! Please let me know if you have any more inquiries.

The following are the important characteristics that separate a truly dedicated sublimation printer from conventional inkjet document printers:

Specialized Dye Inks – Sublimation printers use dye-based inks that, when heated, transform into a gas, allowing the color to infuse into polymer coatings on substrates.

Ink System – A high capacity, sometimes multi-cartridge ink system stores a significant amount of dye ink to suit the color demands of graphics-intensive prints.

Print Head – Print heads have tough nozzles designed to handle strong gel sublimation inks without clogging.

Color Management – Onboard color lookup tables and imaging algorithms designed specifically for sublimation color space requirements.

Print Profiles – Includes onboard print mode and media type profiles for a variety of popular sublimation paper stocks and polymer blanks.

Temperature Control – Tight internal component temperature regulation eliminates ink viscosity variations and nozzle drying when printing on a slower substrate.

Saturation – A special max saturation mode injects huge dye concentrations into prints, frequently 300%+ density versus ordinary 160% ink restrictions.

Print Resolution – Supports extremely high print resolutions, frequently exceeding 1440 x 1440 DPI for photorealistic sublimation transfers.

Essentially, specialized sublimation printers include modified hardware components as well as software calibration that is specifically built for the heat transfer sublimation process requirements that are not found on ordinary inkjet printer models.

In most circumstances, buying a specialist dye-sublimation printer developed exclusively for sublimation printing from the outset is preferable to attempting to convert a regular inkjet document printer using third-party inks and modifications.

Here’s a quick breakdown of the benefits of each route:

Purchasing a Dye Sublimation Printer

Advantages:

→ There are no warranty concerns.

→ Long printhead life – Vibrant, precise colors

→ Fast print speeds

→ Lower ink costs are associated with larger ink cartridges.

Using a Standard Printer to Convert

Advantages:

→ Lower initial hardware costs

→ Potentially makes use of an existing printer

→ An exploring choice for beginners

However, the disadvantages of converting include increased long-term ink costs, color errors, print faults, customizing problems, voiding warranties, and less reliable overall performance.

The bottom line:

While converting document inkjets is a low-cost starting point for testing, most serious hobbyists or enterprises will gain more from investing in an actual engineered sublimation printer outright rather than dealing with key flaws while jury-rigging solutions in the long run.

9 Comments